How to Use Autel PowerScan PS100 Circuit Tester

Autel PowerScan PS100 is a excellent electrical tester.And it will make you work easily for reducing diagnostic time.

What you can do by using Autel PowerScan PS100?

1.Determine at a glance if a circuit is positive, negative, or open without having to reconnect clips from one battery pole to another.

2.Test for continuity with its built-in auxiliary ground lead

3.By depressing the power switch, conduct a positive or negative battery current to the probe tip for testing the function of an electrical component without the use of jumper wires.

Test for poor ground contacts instantly without performing voltage drop tests. The tool is also short-circuit protected; its internal circuit breaker will trip if it becomes overloaded.

4.Follow and locate short circuits without wasting fuses. The tool’s long cable allows you to test along the entire length of the vehicle without constantly searching for suitable vehicle grounds.

How to Use Autel PowerScan PS100 Tester?

Step 1:Power on your Autel PS100

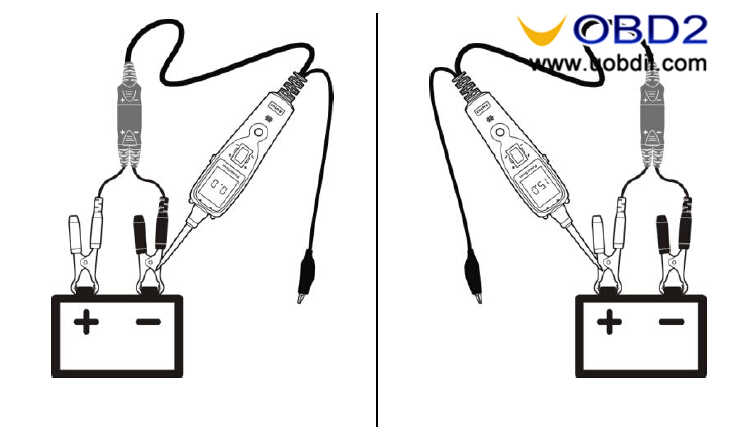

Autel PowerScan PS100 is powered via the vehicle battery.

Connect the RED battery clamp to the positive terminal of the vehicle’s battery,and the BLACK clamp to the negative terminal.When the tool is first connected to a battery(power source),it will sound a beep and the Head Lights will be on to illuminate the test area of the probe tip.

Step 2:Do Quick-Self Test

Before you test a circuit or component, be sure your tool is in good order by doing a quick self-test.

With the tool connected, perform a quick self-test. The power switch is a momentary rocker switch located on the tool’s body. Flanking the switch are positive and negative markings.

Press the Power Switch forward to activate the tip with a positive voltage. The Red LED should light and the LCD display will read the battery voltage. If the tone feature is turned on, a high pitched tone will sound. Let go of the power switch and the LED will turn off and the high tone will cease.

Press the Power Switch rearward to activate the tip with a negative voltage. The Green LED should light and the LCD display will read the „0.0V‟ (ground). If the tone feature is turned on, a low pitched tone will sound. Let go of the power switch and the LED will turn off and the low tone will cease.

Your tool is working correctly and is now ready for use.

IMPORTANT: When powering-up components, you can increase the life of power switch in the tool if you first press the switch, then contact the tip to the component. The arcing will take place at the tip instead of the contacts of the switch.

Autel PowerScan PS100 Circuit Tester Work Modes:

There are four modes to diagnose the electrical systems, which can be accessed by depressing the Mode Button and cycling through each one.

DC voltage

While the tool in this mode, contact the probe tip to a circuit, then the LCD display will read the DC voltage with a resolution of 0.1 volt.

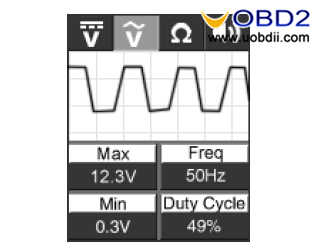

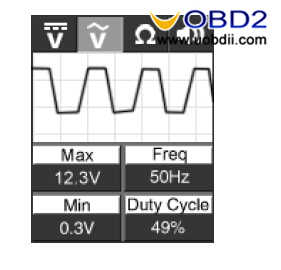

AC voltage

While the tool in this mode, contact the probe tip to a circuit, then the LCD display will read the Max. voltage, the Min. voltage, frequency and duty cycle. ( Figure 4).

Resistance

While the tool in this mode, contact the probe tip to a circuit, then the LCD display will read the Max. voltage, the Min. voltage, frequency and duty cycle.

Tone On/Off

While the tool in this mode, just do a quick press of the mode button to toggle the tone on or off. While quickly pressing (a quick press and release) the mode button, if a short high beep is heard, this means the audio tone is turned on. If a short low beep is heard, the audio tone is turned off.

This function is invaluable when working in bright areas where LED illumination alone is not sufficient. The audio feature may be disengaged when desired, such as for applications where the tool will be connected to circuits for long periods of time and the audio could become annoying.

Voltage & Polarity Testing

While the tool is in DC Voltage mode, contact the probe tip to a POSITIVE circuit. The red LED will light and the LCD displays the voltage with a resolution of 0.1V. If the beep is turned on, a high pitched tone will sound.

If contact the probe tip to a NEGATIVE circuit, the green LED will light and the LCD displays the voltage with a resolution of 0.1V. If the beep is turned on, a low pitched tone will sound.

If contact the probe tip to an OPEN circuit, neither of the LED will light.

Continuity Testing

While the tool is in Resistance mode, using the probe tip with chassis ground or the auxiliary ground lead, continuity can be tested on wires and components attached or disconnected from the vehicle‟s electrical system.

When the probe tip is contacting a good ground, the LCD will indicate “0.0Ω” and green LED will be on. If the tone feature is turned on, a low pitched tone will sound.

In other cases, the LCD only indicates the resistance value.

If the resistance value is greater than 200kΩ, the LCD will show “0L”.

There is also another way to prove continuity of connections to ground or battery. Power up the connection using the power switch. If the circuit breaker trips you know that you have a good solid low resistance connection.

NOTE: You can use the probe tip to pierce the plastic insulation on a wire. This means that you can test the circuit without disconnecting anything.

Signal Circuit Testing

Once you extract a DTC from the vehicle and realize that troubleshooting begins with some kind of sensor circuit, there is a quick test you can perform to verify the code. Testing your sensor is easy while using the tool.

For example, you suspect there is a problem with your M.A.P. sensor circuit, then follow the procedure involved with testing this sensor:

Set the tool in AC Voltage mode, using the probe tip with chassis ground or the auxiliary ground lead.

Connect vacuum pump to MAP sensor.

Contact the probe tip to the MAP sensor positive terminal and observe the LCD readings which should be a sine wave in normal condition.

Apply vacuum.

Release vacuum and observe the LCD readings.

If the LCD readings are abnormal, there is a problem with this sensor.

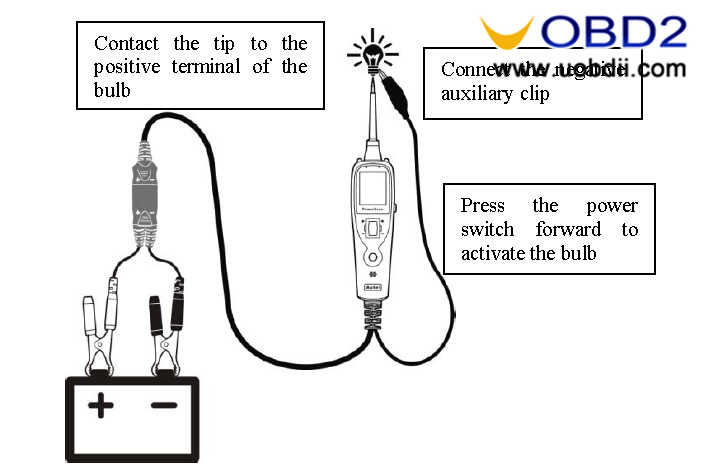

Activating Components in Your Hand

While the tool is in DC Voltage mode, by using the probe tip in connection with the auxiliary ground lead, components can be activated right in your hand, thereby testing their functions.

Connect the auxiliary ground lead to the negative terminal or ground side of the component being tested. Then contact the probe tip to the positive terminal of the component, the green LED should light, indicating continuity through the component.

While keeping an eye on the green LED, quickly press and release the power switch forward. If the green LED went out and the red LED came on, you may proceed with further activation. Rock the power switch forward and hold it down to provide power to your component. With the power switch rocked forward, power will flow from the positive lead on the battery into the probe tip, through the tip into the component‟s positive terminal, into the component and out of the component, through the auxiliary ground lead and back into the tool, and back to the vehicle‟s battery‟s ground.

If the green LED went off at that instant or if the circuit breaker tripped, the tool has been overloaded. This could happen for the following reasons:

The contact you are probing is a direct ground or negative voltage.

The component you are testing is short-circuited.

The component is a very high current component (i.e., starter motor).

If the circuit breaker is tripped, reset it by waiting for it to cool down (15 sec.) and then depressing the reset button.

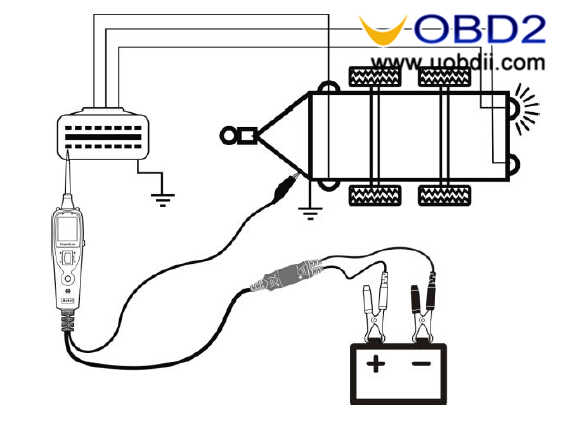

Testing Trailer Lights and Connections

While the tool in DC Voltage mode, clip the auxiliary ground lead to the trailer ground, probe the contacts at the jack and then apply voltage to the probe tip. This lets you check the function and orientation of the connector and trailer lights.

If the circuit breaker tripped, that contact is likely a ground. Reset the circuit breaker by letting it cool down for 15 seconds and depressing the reset button until it clicks into place.

Activating Components in The Vehicle

While the tool in DC Voltage mode, contact the probe tip to the positive terminal of the component, the green LED should light, indicating continuity to ground. While observing the green LED, quickly depress and release the power switch forward. If the green LED went out and the red LED came on, you may proceed with further activation.

If the green LED went off at that instant or if the circuit breaker tripped, the tool has been overloaded. This could happen for the following reasons:

The contact you are probing is a direct ground.

The component you are testing is short-circuited.

The component is a very high current component(i.e., starter motor).

If the circuit breaker is tripped, reset it by waiting for it to cool down (15 sec.) and then depressing the reset button.

WARNING: Haphazardly applying voltage to certain circuits can cause damage to a vehicle’s electronic components. Therefore, it is strongly advised to use the vehicle manufacturer’s schematic and diagnosing procedure while testing.

NOTE: When powering up components, you can increase the life of power switch if you first press the switch, then contact the tip to the component. The arcing will take place at the tip instead of the contacts of the switch.

Activating Components w/Ground

While the tool in DC Voltage mode, contact the probe tip to the negative terminal of the component, the red LED should light. While observing the red LED, quickly depress and release the power switch rearward. If the red LED went out and the green LED came on, you The component is a very high current component(i.e., starter motor).

If the circuit breaker is tripped, reset it by waiting for it to cool down (15 sec.) and then depressing the reset button.

WARNING: With this function, if you are contacting a protected circuit, a vehicle’s fuse can be blown or tripped if you apply ground to it.

Checking for Bad Ground Contacts

Probe the suspected ground wire or contact with the probe tip.

Observe the green LED. Depress the power switch forward then release. If the green LED went out and the red LED came on, this is not a true ground..

If the circuit breaker tripped, this circuit is more than likely a good ground. Keep in mind that high current components such as starter motors will also trip the circuit breaker.

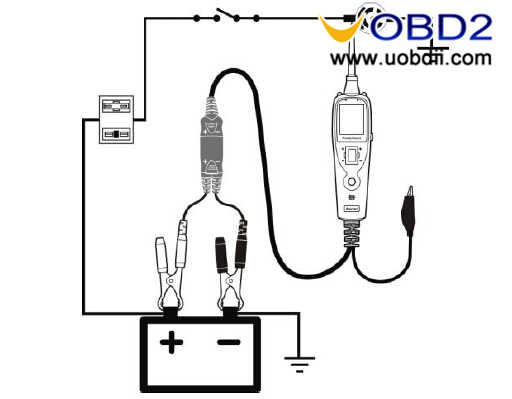

Following & Locating Short Circuits

In most cases a short circuit will appear by a fuse or a fusible link blowing or an electrical protection device tripping (i.e., a circuit breaker). This is the best place to begin the search.

Remove the blown fuse from the fuse box.

Use the probe tip to activate and energize each of the fuse contacts. The contact which trips the circuit breaker is the shorted circuit. Take note of this wire‟s identification code or color.

Follow the wire as far as you can along the wiring harness.

Here is an example for this application.

If you are following a short in the brake light circuit, you may know that the wire must pass through the wiring harness at the door sill. Locate the color-coded wire in the harness and expose it.

Probe through the insulation with the probe tip, and depress the power switch forward to activate and energize the wire.

If the circuit breaker tripped, you have verified the shorted wire. Cut the wire and energize each end with the probe tip. The wire end which trips the circuit breaker again is the shorted circuit and it will lead you to the shorted area.

Red/Green Polarity LED

The Red/Green Polarity LED lights up when the probe tip voltage matches the battery voltage within ±0.8 volts. It is added information that could be valuable to the technician.

If the circuit you are testing is not within a 0.8 volt (plus or minus) of supply voltage, you will see the voltage reading on the LCD but you will not hear a tone or see a red or green LED. This tells you either you have a voltage drop in excess of 0.8 volt from battery voltage or you are probing a circuit that has an increase of a 0.8 volt or more over battery voltage.

To determine battery voltage, simply remove the tip from the circuit and press the power switch forward. Battery voltage will then be displayed on the LCD. The difference between the battery voltage and what is read on the circuit is either voltage drop or voltage increase. This allows you to determine a voltage drop without running back to check the battery. It‟s just another one of time saving feature the tool has.

Src:http://www.uobdii.com/wholesale/autel-powerscan-ps100-electrical-system-diagnostic-tool.html